Introduction

Polyvinyl chloride (PVC) is a ubiquitous material found in countless industries, from construction and healthcare to packaging and automotive. Its versatility stems from its ability to be modified for specific applications. PVC 0.007 plasticized, a modified form of PVC, stands out for its enhanced flexibility, durability, and workability, making it a preferred choice for a wide range of products.

Understanding PVC 0.007 Plasticized

Composition and Properties

PVC 0.007 plasticized is a unique blend of PVC resin, plasticizers, and stabilizers. The addition of plasticizers, such as phthalates or adipates, is crucial in transforming rigid PVC into a flexible material. These plasticizers work by embedding themselves between the PVC chains, reducing intermolecular forces and allowing for greater movement and flexibility.

Stabilizers, like lead or calcium-zinc compounds, are incorporated to prevent degradation caused by heat, light, and oxygen exposure. These additives ensure the long-term stability and performance of PVC 0.007 plasticized.

Key Characteristics

PVC 0.007 plasticized exhibits several key characteristics that make it a valuable material across various industries:

- Enhanced Flexibility: Compared to unplasticized PVC, it offers significantly improved flexibility, allowing it to be bent, shaped, and molded with ease.

- Durability: It demonstrates excellent resistance to wear and tear, making it suitable for applications exposed to harsh environments or demanding conditions.

- Improved Workability: The addition of plasticizers enhances its workability, simplifying processing and fabrication methods like extrusion, injection molding, and calendering.

Applications of PVC 0.007 Plasticized

The unique properties of PVC 0.007 plasticized make it ideal for a multitude of applications:

- Electrical Insulation: Its excellent electrical insulation properties and flexibility make it a reliable choice for wire and cable insulation.

- Medical Devices: Biocompatibility and flexibility are crucial in medical applications. PVC 0.007 plasticized is commonly used in medical tubing, catheters, blood bags, and other medical devices.

- Packaging: Its flexibility, transparency, and barrier protection properties make it a popular choice for food packaging, blister packs, and other packaging solutions.

- Construction: PVC 0.007 plasticized finds application in flooring, roofing membranes, window frames, and pipes, owing to its durability and weather resistance.

Advantages over Unplasticized PVC

PVC 0.007 plasticized offers several distinct advantages over its unplasticized counterpart:

| Feature | PVC 0.007 Plasticized | Unplasticized PVC |

|---|---|---|

| Flexibility | High | Low |

| Workability | Easy | Difficult |

| Temperature Range | Wider | Narrower |

| Impact Resistance | Higher | Lower |

Considerations for Use

While PVC 0.007 plasticized presents numerous benefits, certain considerations are crucial:

- Plasticizer Migration: Plasticizers can migrate out of PVC over time, potentially affecting the product’s performance and raising concerns about environmental and health impacts. Selecting appropriate plasticizers and understanding migration potential is essential.

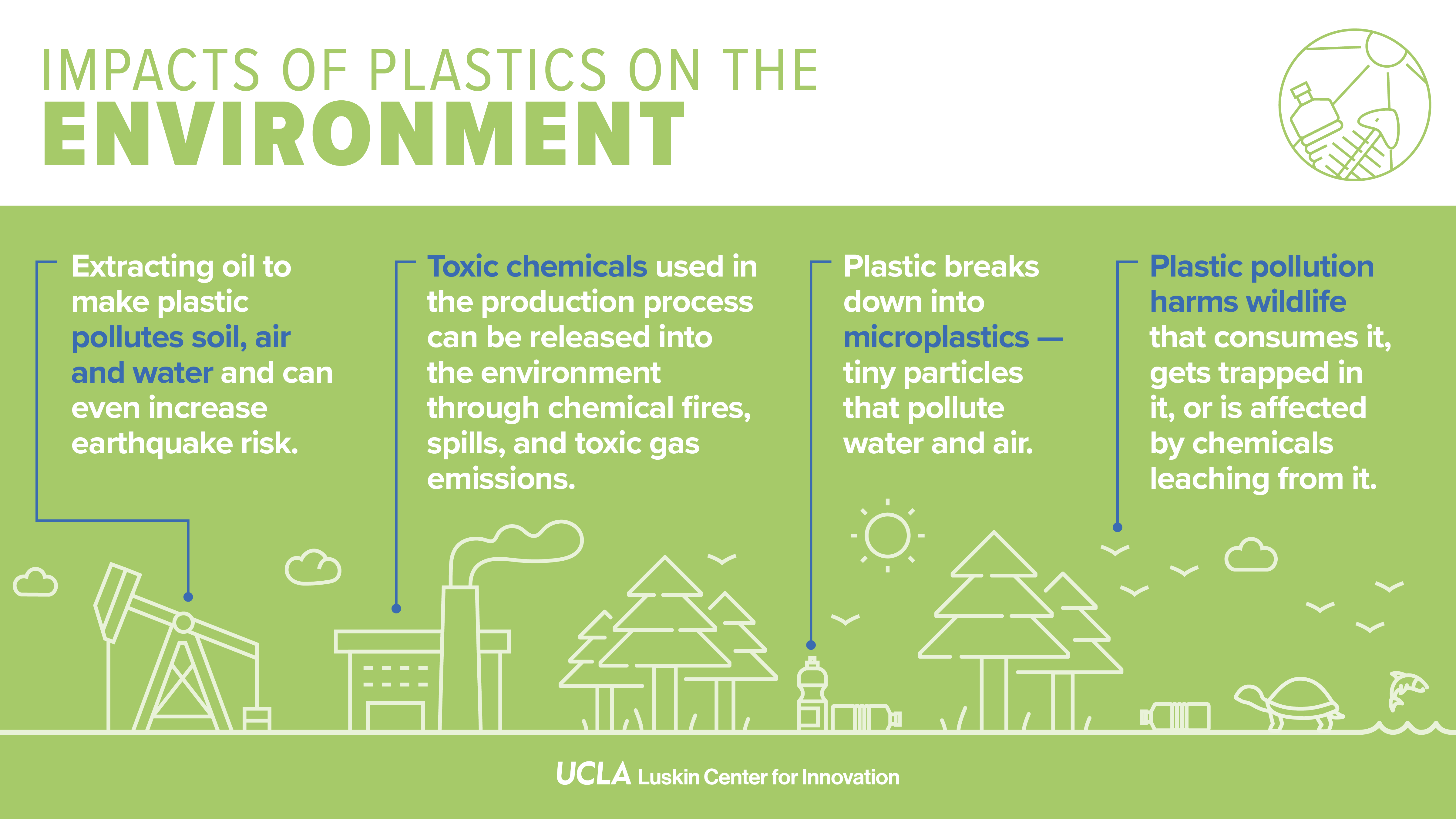

- Environmental Impact: The production and disposal of PVC raise environmental concerns. Sustainable practices, including recycling and the use of renewable resources, are gaining traction to mitigate these impacts.

- Temperature Limitations: The presence of plasticizers can affect the material’s performance at extreme temperatures. Understanding the intended application’s temperature range is vital for optimal material selection.

Market Trends and Sustainability Initiatives

The PVC market is dynamic and responsive to evolving industry needs and environmental concerns.

- Market Growth: As of March 2024, the price for PVC Pipe Grade in the USA was reported at USD 736/MT, indicating a positive pricing environment driven by increased downstream demand and supply constraints in North America 1.

- Sustainable Plasticizers: Companies like Perstorp Group are pioneering the development of sustainable plasticizers derived from renewable resources. Pevalen Pro 100, a PVC plasticizer with 100% renewable carbon content, exemplifies this trend, reducing the environmental footprint of PVC production 5.

- Regulatory Scrutiny: Regulatory bodies like the European Chemicals Agency (ECHA) are actively assessing the potential risks associated with PVC additives, emphasizing the need for ongoing research and responsible use of PVC and its plasticizers 4.

Americorp International: Your Partner in PVC Solutions

Americorp International, a leading global chemical distribution company, offers a comprehensive range of PVC products, including PVC 0.007 plasticized, sourced from reputable producers. Our commitment to quality, competitive pricing, reliable availability, and exceptional customer service makes us a trusted partner for businesses seeking high-performance PVC solutions.

Conclusion

PVC 0.007 plasticized remains a versatile and valuable material, playing a vital role in numerous industries. As sustainability and environmental considerations become increasingly important, the industry is actively developing innovative solutions to address these challenges. Americorp International is dedicated to providing customers with access to the latest advancements in PVC technology, ensuring they have the materials they need to meet their specific application requirements while contributing to a more sustainable future.

Visuals

Caption: PVC’s versatility is demonstrated in its wide range of applications, including pipes, cables, and medical devices.

Caption: Addressing the environmental impact of plastic pollution is a crucial challenge, driving innovation in sustainable materials and recycling practices.