In the ever-evolving world of plastics and polymers, Linear Low-Density Polyethylene (LLDPE) stands out as a remarkably versatile and widely used material. Its unique blend of flexibility, toughness, and impact resistance has made it a staple across numerous industries, shaping everything from packaging and construction to toys and automotive parts. This comprehensive guide delves into the properties, applications, benefits, and recent developments of LLDPE, highlighting its crucial role in our modern world.

What is LLDPE?

LLDPE is a thermoplastic polymer derived from the monomer ethylene. Its molecular structure consists of long, linear chains with minimal side branching. This distinct structure grants LLDPE its exceptional properties, making it stronger, stiffer, and more resistant to environmental stress cracking than its predecessor, Low-Density Polyethylene (LDPE).

Key Properties of LLDPE

- Flexibility and Toughness: LLDPE can withstand significant bending and deformation without fracturing, making it an ideal choice for applications requiring both flexibility and durability.

- Impact Resistance: The material’s ability to absorb and dissipate impact energy effectively prevents cracks and fractures, making it essential for applications involving potential shock or impact.

- Chemical Resistance: LLDPE exhibits strong resistance to a broad spectrum of chemicals, including acids, alkalis, and solvents, enabling its use in harsh or demanding environments.

- Puncture Resistance: LLDPE’s robust structure provides excellent resistance to punctures and tears, further enhancing its suitability for packaging and protective applications.

- Moisture Barrier Properties: LLDPE acts as an effective barrier against moisture, safeguarding products from spoilage and damage.

Applications of LLDPE

The versatility of LLDPE is reflected in its extensive range of applications across various industries:

- Packaging: LLDPE reigns supreme in the packaging industry, particularly in films. Its flexibility, strength, and clarity make it ideal for grocery bags, shrink wrap, food packaging (both fresh and frozen), and heavy-duty industrial packaging.

- Construction: LLDPE’s durability and resistance to environmental factors make it a valuable asset in construction. It’s used in geomembranes for landfills and ponds, pipe liners to protect against corrosion, and cable insulation.

- Consumer Goods: From toys and housewares to storage containers and furniture, LLDPE’s flexibility and durability contribute to the creation of a wide range of consumer products.

- Automotive Parts: In the automotive sector, LLDPE finds application in fuel tanks, underbody protection, interior components, and even parts of the car’s body, leveraging its strength and impact resistance.

- Medical Devices: LLDPE’s biocompatibility, flexibility, and resistance to sterilization processes make it a suitable material for medical devices, including tubing, packaging for sterile products, and components of medical equipment.

- Agriculture: LLDPE films are used in agriculture for greenhouse coverings, mulch films, and silage covers, enhancing crop production and protecting against weather conditions.

Benefits of Using LLDPE

LLDPE offers numerous advantages over other polymers, solidifying its position as a preferred choice in many applications:

- Cost-Effectiveness: LLDPE is a relatively inexpensive polymer compared to other options, offering a cost-efficient solution without compromising performance.

- Easy Processing: The material can be readily processed using various methods, including extrusion, injection molding, and blow molding, making it highly adaptable to different manufacturing needs.

- Recyclability: LLDPE is recyclable, contributing to a circular economy and reducing environmental impact. Many products made from LLDPE can be recycled into new items, conserving resources and reducing waste.

- Lightweight: LLDPE’s low density results in lightweight products, reducing transportation costs and making it easier to handle and use.

Latest Developments in LLDPE (2024 and Beyond)

The LLDPE market is dynamic and constantly evolving. Here are some key recent developments that are shaping the future of this versatile polymer:

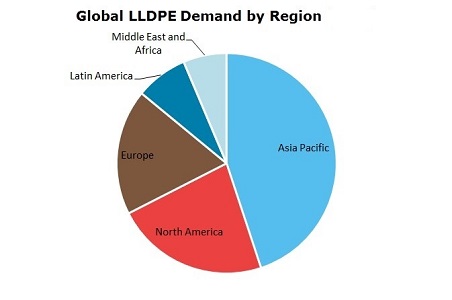

1. Market Growth: The global LLDPE market is experiencing robust growth and is projected to reach approximately $60 billion by 2024. This growth is fueled by increasing demand in sectors such as retail packaging (e-commerce boom), automotive (lightweighting trends), and agriculture (growing population and food security concerns).

2. Price Trends: LLDPE prices are influenced by various factors, including crude oil prices, feedstock availability, and regional demand. Recent trends show a positive trajectory in Europe due to supply shortages and increased demand, while the Asia-Pacific region has seen a bearish trend due to economic slowdowns and reduced demand from China.

3. Sustainability Initiatives: The LLDPE industry is increasingly focused on sustainability. Manufacturers are actively developing recyclable and environmentally friendly LLDPE products, aligning with global sustainability goals and consumer demand for eco-conscious choices. This includes using recycled content in LLDPE production and developing biodegradable or compostable LLDPE alternatives.

4. Technological Advancements: Innovations in processing technologies are driving improvements in LLDPE production efficiency and quality. These advancements enhance the material’s properties, expand its applications, and lead to more tailored solutions for specific industries. For example, metallocene catalysis is enabling the production of LLDPE with improved strength, clarity, and processability.

5. Emerging Applications: New and exciting applications for LLDPE are constantly being explored. The medical sector is seeing increased use of LLDPE in advanced packaging solutions for pharmaceuticals and medical devices, while the agricultural sector is leveraging LLDPE for protective films that enhance crop yields and reduce water consumption.

Visualizing LLDPE Market Trends

Global LLDPE Demand by Region (2013)

Americorp International: Your Source for LLDPE

Americorp International is a leading global distributor of LLDPE, offering a diverse range of grades to cater to the specific needs of our customers. Our commitment to providing high-quality products, competitive pricing, and exceptional customer service makes us a trusted partner in the polymer industry.

Explore our Americolene brand for specialized plastic raw materials and discover how our expertise can benefit your business. Learn more about our global presence and subsidiaries to understand our extensive reach and local market knowledge.

Conclusion

LLDPE is a remarkable polymer with an impressive array of applications across diverse industries. Its unique combination of versatility, strength, durability, and cost-effectiveness makes it an indispensable material in our modern world. As the demand for LLDPE continues to grow, Americorp International remains dedicated to providing our customers with the highest quality LLDPE solutions and expert support. We are committed to staying at the forefront of industry advancements, offering innovative products and services that meet the evolving needs of our clients.